As modern cars and light trucks continue to grow in complexity, their maintenance needs are changing. Component failures that were commonplace just a decade or two ago are becoming much less common today.

An example of this is the throttle-position sensor (TPS). This small plastic sensor would be mounted on the throttle body, usually on the opposite of the throttle cable. The TPS was used to tell the engine control unit (ECU) what angle the throttle body was being opened to by the driver, and the ECU would adjust the fuel as needed based on this data as well as other inputs.

A faulty TPS reading can cause a number of drivability concerns, including:

• Unexplained bucking or jerking of the engine

• Surging engine idle

• Engine stalling, stumbling or hesitation

These sensors were rather inexpensive and usually pretty easy to replace. They didn’t fail too often, but I can remember having to replace them on a few of my own vehicles, as well as some customer vehicles. So what happened to throttle-position sensors, and why don’t we see them as often today?

Throttle-By-Wire

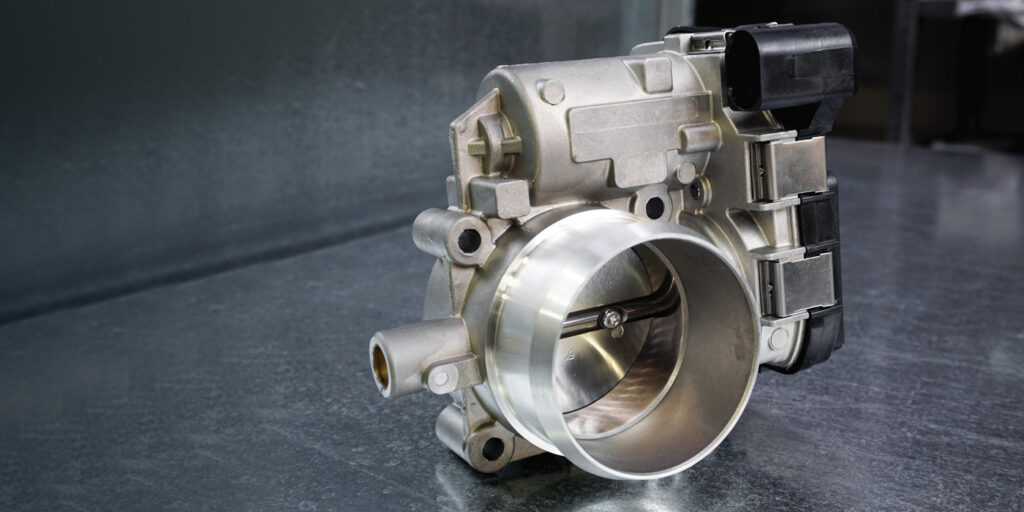

Throttle-by-wire technology has been called by many names, but it operates on a simple principle – an electronic throttle body is used to meter the air entering the engine. This electronic throttle body is controlled by the ECU based on a number of inputs including accelerator-pedal position, mass airflow, manifold air pressure, wheel speed and more. But the important thing to understand is that there is no longer a mechanical link between the accelerator pedal under the dashboard and the throttle body on the engine. So why is this important?

By decoupling the accelerator pedal from the throttle body, automakers are able to precisely control the throttle angle in all operating conditions to maximize throttle response and traction, reduce emissions and improve fuel economy. Throttle-by-wire systems are able to maximize the benefits of variable-valve timing and direct fuel injection by precisely controlling how much air is introduced to the engine.

With the advent of throttle-by-wire systems, we’ve seen a change in how the ECU measures the throttle position. The TPS still is being used today, but it’s now incorporated into the electronic throttle body. In fact, some electronic throttle bodies may contain more than one TPS. By using multiple sensors, the ECU can monitor and compare both sensor inputs. Redundancy in electronic systems can be a very good thing.

We’ll talk more about the pros and cons of throttle-by-wire a little bit later, but the fact that the TPS is now incorporated into the electronic throttle body can be a big drawback down the road. You see, it means that the system is now less serviceable than it was in the past. If a TPS failed on a cable-driven throttle body, you could replace the sensor for around $30 to $40 and be back on the road. If a TPS fails inside an electronic throttle body, now you have to replace the entire unit, and that could cost hundreds of dollars.

Then, after the electronic throttle body has been replaced, you’ll need to perform a “relearn procedure” so the ECU can learn how the new throttle body reacts to input, and where the internal mechanical stops are located. Failing to perform this critical step can cause a number of drivability concerns, and a costly customer comeback.

There has been a trend in the automotive space for quite some time now where components are becoming more and more “modular.” When I say “modular,” I really mean “pre-assembled.” After all, vehicles are engineered to go down the assembly line as fast as possible. They’re not engineered to be easy to work on. So it makes sense that automakers would get creative with incorporating certain components together into a modular assembly that can be installed more quickly. Of course, the major drawback with this idea is that the replacement costs are increased, and that cost will eventually fall onto the vehicle owner once the warranty period expires.

Advantages & Disadvantages of Throttle-By-Wire

Throttle-by-wire systems offer a number of advantages. They contain fewer moving parts, so that means less maintenance and lower overall vehicle weight. Their precision allows for improved fuel economy and reduced tailpipe emissions, as well as a better overall driving experience for the typical driver. Finally, the throttle body can be used to help the traction or stability control regain vehicle control.

These systems also have a few drawbacks. They’re more expensive to develop, manufacture and replace. They’re more complex due to the wiring and electronic control units that are used. Some drivers may complain about a time delay or “lag” in engine response after they change their accelerator-pedal input.

Finally, they’re harder to service for technicians. Sure, there aren’t any cables or linkage points to grease or maintain, but the real difficulty lies in the electronic controls. Complex wiring and communication systems are needed in order to control the electronic throttle body and related systems. There also are special procedures that must be followed whenever servicing the electronic throttle body. If an electronic throttle body is replaced, the relearn procedure must be performed. This has a profound effect on engine performance, drivability and idle quality.

If you find yourself selling a replacement electronic throttle body to a customer, there are a few questions you should be asking. Do they have a scan tool that’s capable of bi-directional control? A simple code reader won’t work here. They need the real thing in order to relearn the new electronic throttle body. Many electronic throttle bodies are installed in plastic intake manifolds, so it’s a good idea to sell them a new throttle-body seal as well. Finally, it’s a good idea to check with the customer to see if they’ve inspected the wiring harness and connections for any signs of rubbing, fraying or other issues. These sorts of problems can come back to bite them later on down the road.