Back in the 1950s, oil filters were optional on many cars and not even offered on others. On applications where an oil filter was available, it was a cartridge-style filter mounted inside a steel canister. Filter changes required opening the lid on the canister to replace the filter inside, or removing the entire canister so it could be cleaned out and a new filter installed. In the mid-1950s, the first spin-on oil filters were introduced. Spin-on filters quickly became popular because they made oil changes easier and less messy.

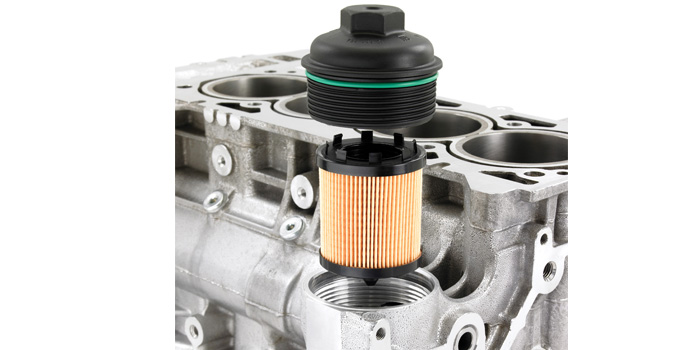

The dirty filter could be spun off and quickly replaced with a new one when the oil was changed. By the 1960s, spin-on filters were the norm and old cartridge style filters had faded into automotive history. Recently, cartridge-style oil filters have made a comeback. These are not the same type of filters that were used 60 years ago, but the basic concept is still the same. Why would cartridge-style oil filters be reintroduced on today’s cars? One is cost. A bare filter is less expensive to manufacture than one that is sealed inside a metal can. With a bare cartridge, there’s no can that has to be replaced and discarded every time the oil is changed.

Mounting the oil filter housing on top of the engine rather than underneath also makes for easier access and less mess. But, the main reason for the change is to make oil filter disposal more environmentally friendly. The metal can around a spin-on oil filter traps a lot of oil inside. Allowing the filter to drain for 24 hours allows much of the oil to escape, but not all.

If the filter is disposed of in a landfill, this residual oil can eventually seep out and contaminate ground water. The metal portion of the filter can be recycled but that requires cutting the filter apart to recover the metal. With a bare cartridge oil filter, there is no metal can or other internal parts other than a bypass valve.

No can means it traps less oil. Also, the filter element can be burned leaving minimal residue for subsequent disposal. Make no mistake that today’s cartridge-style filters are not the same technology that was used back in the 1950s. Most of these late-model cartridge style filters use some type of synthetic microfiber or mesh to provide superior filtering efficiency and longevity. Today’s longer service intervals require a filter that can go the distance between oil changes. For vehicle applications with extended oil drain intervals of 7,500 miles or longer, a premium or ultra-premium quality oil filter should be used as well as a premium quality motor oil such as a full synthetic or synthetic blend with an additive package that can safely handle longer drain intervals.

Premium oil filters, whether they are a traditional spin-on filter or a bare cartridge filter, use higher-grade materials and construction to assure maximum filtering efficiency (typically up to 99 percent) and extended longevity. An inexpensive economy filter with a simple cellulose filter media will do an adequate job of trapping particles down to about 25 to 30 microns in size, but will allow most of the smaller particles to slip right through. Small particles can cause just as much engine wear over time as larger particles, so it’s important to keep the oil as clean as possible with a high efficiency filter.