Screeching, squealing and vibration – this is what can happen when brake hardware isn’t replaced during routine brake jobs. Many technicians and DIYers tend to overlook brake hardware because it can often be reused if it’s not too beat up. But why take a chance? Unwanted traits such as noise and vibration often can result in a comeback for the shop and may lead to parts being returned or replaced under warranty.

One of the most common complaints after a brake job is noise. Brake hardware is designed to make the friction material (brake pads or shoes) work more efficiently and reduce any annoying squeaks, rattles and vibrations. If the brakes are making noises after a brake job, it may be that the hardware wasn’t replaced. It also could be that the hardware wasn’t installed correctly (but let’s assume it was, for this discussion).

When performing a brake job, techs should pay careful attention to the entire brake system, not just the parts that are being replaced. Are the rotors in good condition? Do the brake sliders work smoothly? Are there signs of corrosion on the hardware? Can you tell if any hardware pieces are missing? Are the dust boots that protect the sliders and piston ripped or missing altogether? These are a few things that should be on the checklist for any brake job.

Counter pros always should ask customers about the brake hardware whenever new brake components are purchased. It’s like asking if the customer wants fries with their hamburger and Coke. They may not think about it at first, but most people will want it if you suggest it to them. Same goes for silicone grease. Most shops have a lot of that already, but you never know if they need more. DIYers almost never have grease, so be sure to package it all together, including the chemicals to clean the brakes.

The hardware needed for each brake job can vary depending on the type and design of brakes. Drum brakes use a lot more hardware than disc brakes. There are many springs, clips and retainers that hold the brake shoes in place on the backing plate. The hardware holds the shoes away from the drum when the brakes aren’t in use. Brake manufacturers make the hardware available in kits that contain all of the fasteners for each axle (that’s two sides).

Disc brakes require different hardware than drum brakes. Disc brakes have calipers that are mounted to a bracket. The caliper or pad sits on slide pins, which allow the caliper (or pads) to slide back and forth as the brakes are engaged. The biggest issue with disc brakes is the pins rust and freeze up and may need to be cleaned and greased or, in many cases, replaced when doing a brake job.

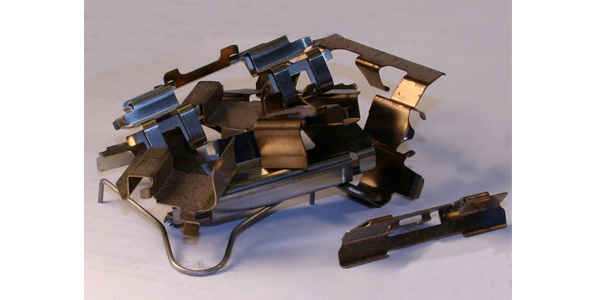

Disc-brake hardware kits also typically contain “fit kits,” which are thin metal pieces that fit on the caliper bracket to allow the pad to slide easily. These pieces also keep the pads from rattling or squeaking in the bracket. Some disc brakes also come with spring clips that pull the pads off the rotor. These are called “pad spreaders,” and they also reduce noise, heat and vibration in the brake system.

Some parking brakes also are set up as a brake drum within the rear rotor hat. This auxiliary drum brake is activated by the parking-brake lever or pedal and uses the same type of hardware as a regular drum brake. While brake hardware is often overlooked, it’s not the best practice to continually reuse old hardware. If it’s missing or bent from a previous job, the technician performing the service may not realize there was a problem in the first place. To maintain the best performance, recommend brake hardware kits to your customers whenever brake parts are ordered.