With its Cleaner Mobility Platform, Mann+Hummel has set out to prove that emission-neutral driving without particulate-matter pollution is already possible.

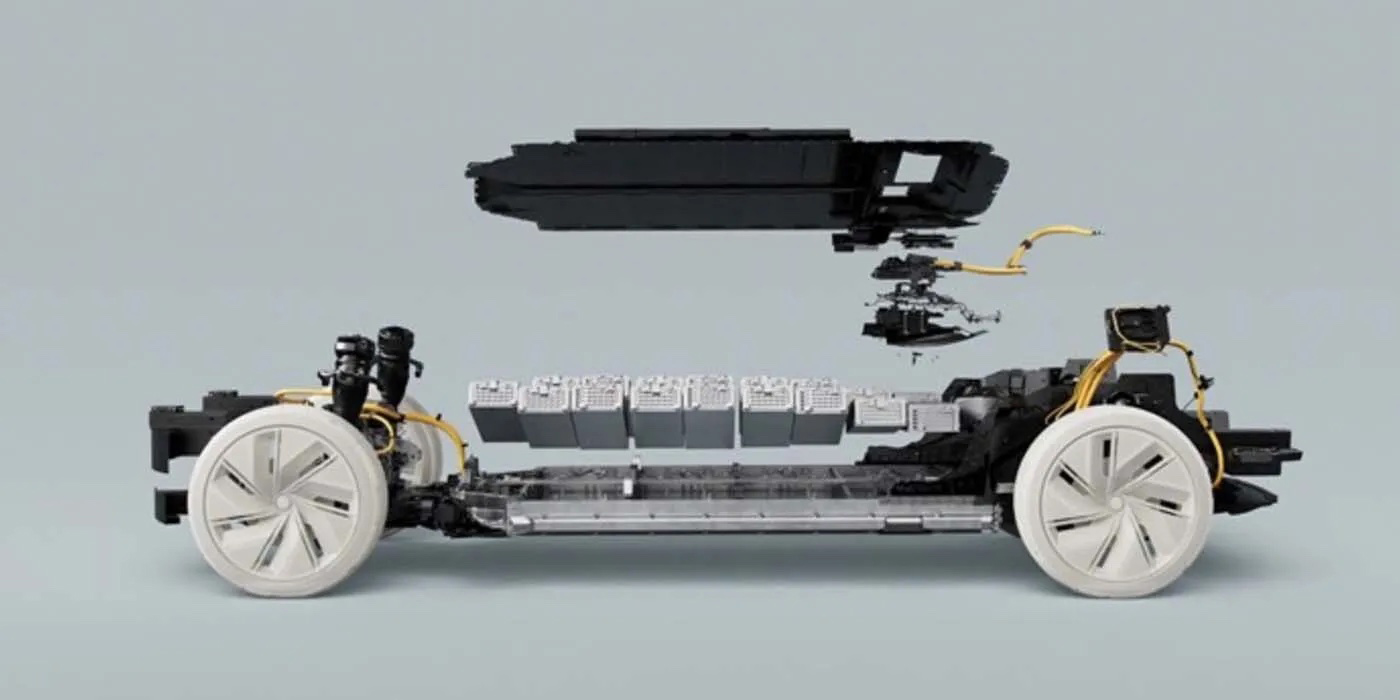

The platform consists of a small electric car as a technology carrier equipped with Mann+Hummel products. These products have helped the vehicle transform into an emission-neutral vehicle, according to the company.

The products installed in the vehicle include:

- The company’s smart cabin-air filtration system, which analyzes cabin and ambient air, activating an on-demand HEPA filter to remove harmful ultra-fine particles from both incoming and circulating cabin air. In addition, an activated carbon filter in the system reduces hazardous pollutant gasses such as SO2, NO2 and VOCs, the company said.

- Mann+Hummel brake-dust-particle filters, which are mounted directly on the brake and reduce particulate matter.

- Integrated fine-dust filters, which are installed between the radiator and bumper and can transform cars, trucks vans and buses into mobile fine dust particle filters.

- The company’s Cyclo-Multi-Sorber energy-saving and interior air-quality system, which adsorbs moisture in the vehicle interior and ensures clear visibility. It also adsorbs CO2 exhaled by passengers – which triggers drowsiness at higher concentrations. The absorber units are automatically regenerated in the process, which saves energy, the company said.

“We installed our filtration systems in an electric vehicle to show how sustainability goals can be achieved quickly and effectively with sophisticated technology,” said Markus Kolczyk, vice president, original equipment and global engineering. “In the mobility sector, this is our contribution to a cleaner environment, based on 80 years of knowledge, experience and research.”

The company said initial field tests and laboratory measurements with the vehicle showed that Real Zero Emission, better indoor air quality and energy savings can all be achieved with these technologies. In addition, the company said its brake dust particulate filters can reduce particulate matter by up to 80%.