When I hear good and bad in the same sentence, I think of the classic Clint Eastwood movie, “The Good, the Bad and the Ugly.”

This isn’t the Old West, but I can draw a perfect parallel between the title and the fight we sometimes have with alternators.

When they’re good, they’re good. When they’re bad, they’re bad. So, what’s the ugly? That’s when they’re good, but we think they’re bad because there’s an electrical problem that prevents them from working properly. It gets even uglier when the problem is hard to find, and probably the ugliest when a good alternator is called bad.

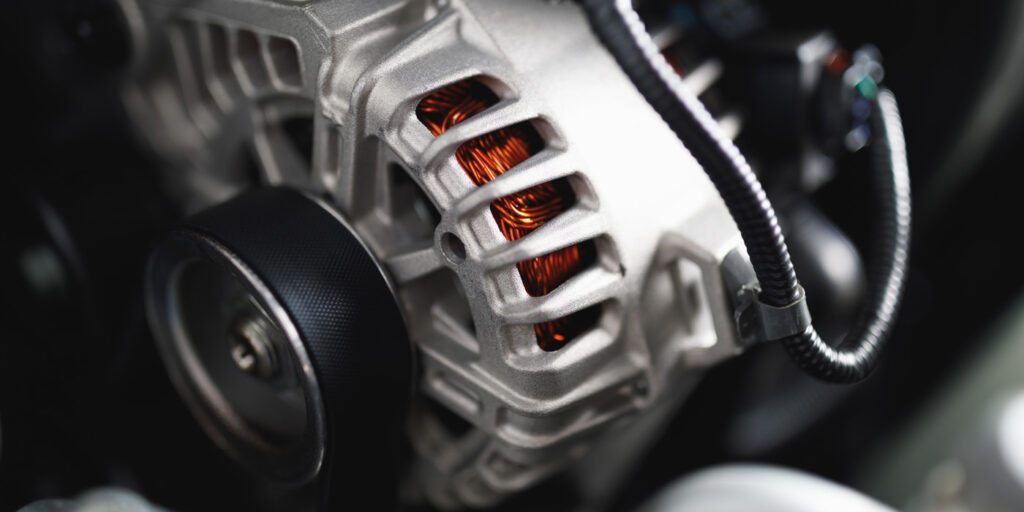

What an alternator does is simple, or at least we’ll keep it that way for now. It outputs direct current (DC) to power vehicle electrical systems and maintain and recharge the vehicle battery. An alternator is aptly named because it generates an alternating current (AC), which is, in turn, converted to DC.

We can divide the alternator into two different systems: the mechanical and the electrical. On the electrical side, you have the components that are responsible for generating and managing the electrical current, which include the rotor, stator, regulator and rectifier. The rotor and stator are the main components that generate electricity, based on fundamental electromagnetic principals. The regulator is what controls the output of the alternator, and the rectifier is what converts AC to DC.

The Good

When an alternator is good, alternating current is being generated by the rotor and stator, the rectifier is converting it to direct current and the regulator is controlling the output. If a problem develops with one of these, the result is either no voltage, too much voltage or an AC-voltage output. Any of those are bad.

If this seems too simple, it is on purpose. We can get much deeper into it, which will make it more difficult, but the way we do things today has changed the process of diagnosing the charging system. Things were different years ago. We used to take alternators apart. We’d check the windings of the rotor and stator. Then we’d check the diodes in the rectifier, and finally check the regulator. As a matter of fact, regulators used to be separate from the alternator and they were mechanical devices compared to solid-state electronics. We’d take everything apart, check it all, determine what was bad and replace only what was needed.

We don’t do that anymore. Alternators have been self-contained for many years. Regulators are built in. If an alternator isn’t working, we replace it. That’s it. We don’t think about why, nor do we even toy with the idea of taking it apart. Just send me a new one.

On the mechanical side, you have the bearings that support the rotor, and the pulley that’s driven by the belt. If the bearings are bad, they’re loose or noisy. Pulleys used to be fixed chunks of metal. Now we see overrunning alternator pulleys (OAP) or overrunning alternator decouplers (OAD). When these go bad, they’re often noisy, or they may not spin the alternator.

The brushes in an alternator are another mechanical part of it. They’re made of conductive materials that physically contact and rub against the slip rings. This is how the electrical current from the regulator flows into the rotor. But we don’t replace brushes anymore, nor do we replace bearings. We don’t even think about taking the alternator apart. We just replace it. The pulleys are the only parts we may replace separately.

The Ugly

When an alternator needs replaced, the process usually isn’t too difficult, but that’s when it can get ugly.

As counter professionals, you deal with technicians, and you deal with do-it-yourselfers. Either way, when they ask for an alternator, you’re hoping the diagnosis is correct. The last thing you want is an alternator return. You might ask a few questions to see if they’ve done some basic diagnosis, but you’re in a tough spot. You don’t want to show disrespect, but you don’t want the original coming back covered in grease, because they found the “real” problem after they replaced it and it didn’t fix the problem.

Do DIYers make mistakes? You bet. Do professional technicians make mistakes? We sure do. It’s not always easy, and diagnosis can be difficult. Any time electrical diagnosis is involved, the potential for mistakes can be greater, and charging systems are no exception. One problem is that alternator failure isn’t uncommon, and if the charging-system indicator is illuminated, that’s likely the problem.

It’s easy to see the warning light, and even maybe check battery voltage with the engine running. If the battery voltage is at or below 12.6 volts, the alternator must be bad, right? After all, we would normally see 13.5 to 14.5 volts. This is what I like to call a reactive diagnosis. We react based on what we know is common and think that what we initially see tells the story. Sure, it’s possible that the alternator may be bad, but only possible. A fact of electrical diagnosis is that the majority of all electrical problems are caused by higher-than-normal resistance – in other words, a poor connection.

Diagnostic Tips

How, as technicians do we keep from making this mistake? We have to remember that electrical systems are far more complicated than they have been for years, and they require correct system voltage in order for all of the computers and electronics to work properly.

Battery condition is critical, and a weak battery can prevent an alternator from properly charging. It’s also not unheard of to get a vehicle in that has both a bad alternator and a bad battery. It does happen.

When diagnosing charging systems, an important detail not to overlook is performing a voltage-drop test on the battery and alternator cables. It’s safe to say that higher than normal resistance is responsible for the good majority of misdiagnosis and comebacks.

The traditional tools we use for battery and charging-system diagnosis are a digital battery tester, a multimeter, a load tester and an amp clamp. However, for modern charging-system diagnosis, a scan tool has become a must-have. Modern charging systems are no longer stand-alone systems, with the vehicle ECM playing a large part in their control and operation.

A power-management system is a more accurate name than charging system, and it includes the alternator, battery and ECM. These systems have been developed to improve fuel economy, battery life and alternator operation, and not only do they monitor battery condition, but some systems also can estimate battery condition as well. They control and adjust charging output and they also can perform diagnostics and set diagnostic trouble codes. Good alternators can go bad, but if you’re faced with answering questions and giving advice to your customers at the counter, make sure they’re covering all the bases of diagnosis, so a good alternator doesn’t turn ugly.