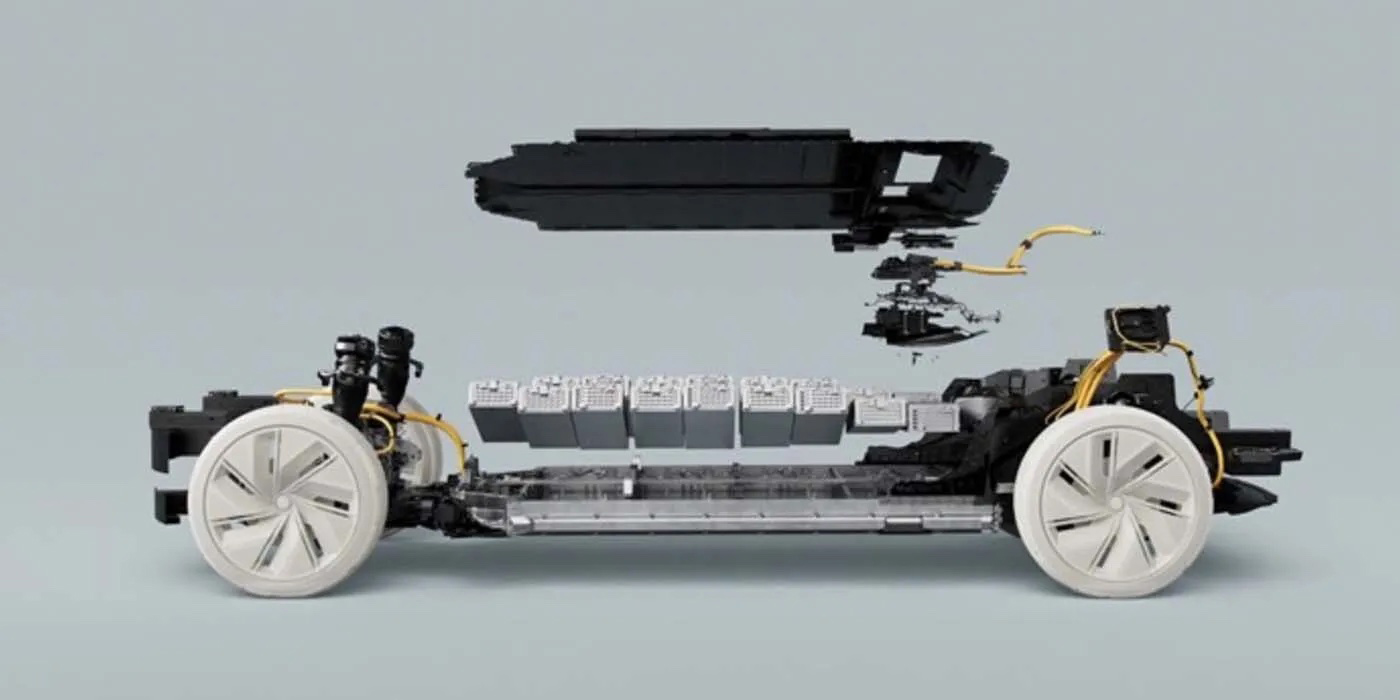

ZF Aftermarket has expanded its product range for electric drivetrains by introducing tailor-made repair kits for electric axle drives.

The introduction of the kits comes on the heels of the company’s previous release of ZF Lifeguard e-Fluids, developed for electric and hybrid vehicles.

The new repair kits provide spare parts for 43 different repair scenarios on electric axle drives, as more electric vehicles fall out of the manufacturer’s warranty period and require maintenance and repair. The kits include all necessary spare parts, fastening elements and tools required for each repair, and are designed to enable repairs without removing the electric drive, according to ZF Aftermarket.

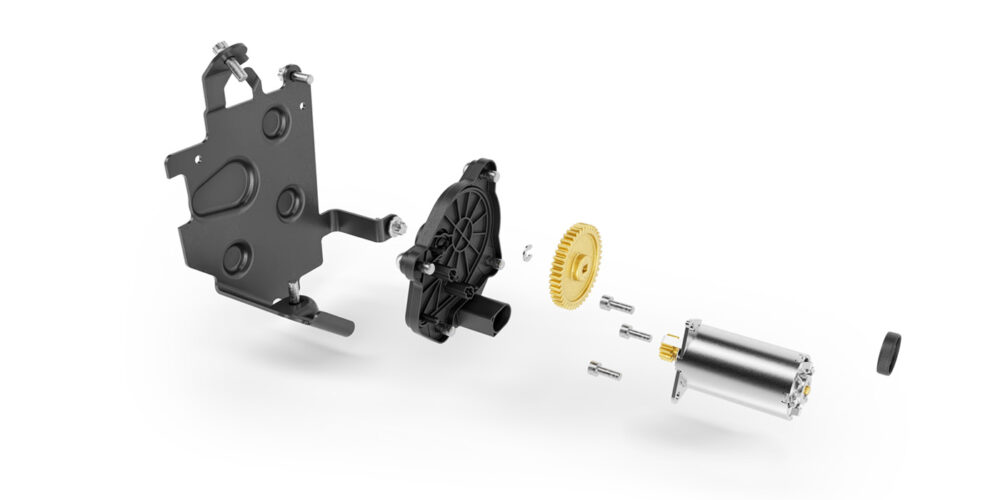

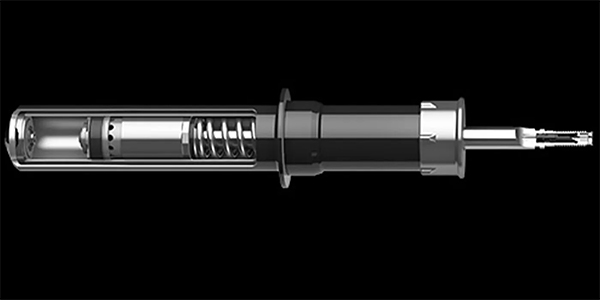

Common repairs that can be performed with the kits include replacing leaking coolant connections, repairing defective parking locks, changing speed or temperature sensors and replacing engine mounts, particularly after accidents, according to the company.

ZF is making the kits available through its aftermarket division, marking the first time the company has offered such products to the independent aftermarket. The kits are designed to address the increasing number of EV repairs handled by independent shops.

However, ZF Aftermarket emphasizes the need for specialized training for these repairs. Shops must ensure that only personnel with high-voltage training carry out the relevant work.

The 43 kits are available for order. They will be publicly presented at the upcoming Automechanika Shanghai, scheduled for Nov. 29-Dec. 2.