Read up on essential products in our annual technical sales seminar section. We review 12 products you need to know better to move products.

Brakes

Fuel Pumps

Gaskets

Batteries

Wipers

Catalytic Converters

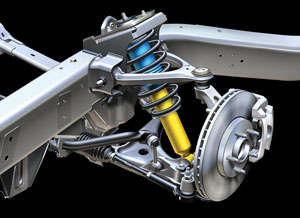

Shocks

Engine Management

Lighting

Belts and Hoses

Oxygen Sensors

Antifreeze

When does a vehicle need new shocks? When the vehicle owner is unhappy or dissatisfied with the way their vehicle rides or handles, or when the original equipment shocks are found to be worn or defective.

Shocks (and struts) do not have a specific time or mileage replacement interval. In fact, many vehicles reach the end of the road with the original dampers still in place. That does not mean the original shocks and struts went the distance and were still in good condition. Most probably were not. More likely, the owners of these vehicles never realized their dampers needed replacing, or if they did, they saw no urgency to do so. Bad shocks won’t prevent a car from starting or driving. But they can make a vehicle unsafe.

Shocks (and struts) do not have a specific time or mileage replacement interval. In fact, many vehicles reach the end of the road with the original dampers still in place. That does not mean the original shocks and struts went the distance and were still in good condition. Most probably were not. More likely, the owners of these vehicles never realized their dampers needed replacing, or if they did, they saw no urgency to do so. Bad shocks won’t prevent a car from starting or driving. But they can make a vehicle unsafe.

For these reasons, many shock manufacturers recommend replacing shocks and struts every 50,000 miles for preventive maintenance. Installing new dampers will restore like-new ride control and handling, and reduce the risk of bad things happening when good shocks go bad. Shocks and struts are part of the “Safety Triangle” (Steering, Stopping and Stability). By dampening the motions of the suspension, the shocks and struts help keep the body stable and controllable when braking and cornering. This is especially important in Sport Utility Vehicles that have a high center of gravity. Excessive body roll when cornering hard or making sudden steering maneuvers increases the risk of the driver losing control and skidding or rolling the vehicle.

Good shocks also improve traction, tire life and steering stability. When tires bounce over bumps and dips in the road, they may lose their grip on the road if the suspension isn’t dampened. Weak shocks that allow excessive tire bounce can increase tire wear and cause a cupped wear pattern on tires. Weak shocks also can increase a vehicle’s stopping distance on a rough road. Steering harshness, jolts and shimmy after hitting a bump can be additional symptoms of worn or ineffective shocks.

Motorists who use their vehicles for towing or hauling heavy loads also may experience bottoming and handling problems if their shocks are not up to the task. For these kinds of applications, air-assist or overload shocks are a good upgrade.

A bounce test is still a valid means of identifying weak shocks and struts. Rock the suspension several times up and down, then release it. If the dampers don’t stop the motion within once bounce, the shocks are weak and should be replaced.

Other symptoms of worn shocks include suspension bottoming after hitting a bump, excessive nose dive when braking, excessive body lean or sway when cornering, a bouncy or undulating ride, wheel shudder or shimmy after hitting a bump, and cupped tire wear.

“Shock fade” on a rough road (a noticeable loss of ride control after a short period of driving) usually means the high-pressure gas inside a gas-pressurized shock has escaped. The gas charge helps prevent cavitation and foaming of the hydraulic fluid inside the shock.

Worn shocks and struts should always be replaced in pairs (both fronts, both rears or all four) to maintain even ride control.

Many late-model vehicles are factory-equipped with specialty shocks or struts. Some have adjustable electronic shocks. These can be very expensive to replace, or may not be available in the aftermarket. In many instances, original equipment electronic shocks can be replaced with conventional shocks to save your customer money. The trade-off, however, is that it disables the electronic ride control system. The same goes for air-ride and air-assisted self-leveling suspensions. Air leaks are always a problem with air suspensions. Leaks can occur in the air springs, lines or fittings.

This often leads to a compressor failure (from constantly running), leaving the suspension flat. The original equipment air ride components can be very expensive to replace, so a cost-saving option is to install a conventional strut conversion kit.