Advanced Driver Assist Systems (ADAS) Overview:

Advanced Driver Assist Systems have been quite the industry buzz over the last several years. We have seen new business opportunities arise, and even a new segment of mobile technicians focusing on ADAS calibrations. While ADAS may seem relatively new, automotive service professionals have been servicing Driver Assist Systems for decades now. Systems like power steering, power brakes, and cruise control have been assisting motorists for many years. What is different with ADAS is that we now have input devices to understand what the driver’s intent is and alert the driver to potential dangers, rather than relying solely on the driver’s sight and sound.

The Four Horsemen of ADAS

ADAS input devices can be divided into four primary categories.

Ultrasonic

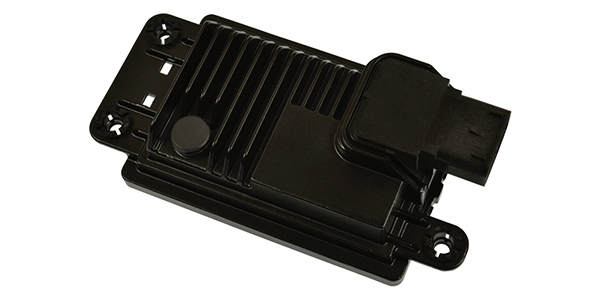

The “ultrasonic” category encompasses devices like park assist sensors and blind spot detection modules. Ultrasonic sensors are relatively simple and are great at measuring distance.

Radar

The next category is “radar”. Radar is more complicated than the ultrasonic category and is great at measuring distance and relative speed. We see radar used frequently in adaptive cruise control systems.

Optical

The third category is “optical”, and as you might imagine, this essentially encompasses cameras. These devices will identify objects and be used for things like lane keep assist or parking assistance.

Lidar

Finally, the fourth category is “lidar”. Lidar is the most complex, yet most accurate input available and will produce 3D mapping. This is currently not a very popular ADAS input, but will be gaining popularity in the next few years as development costs have been significantly reduced.

How does ADAS work?

In addition to the input devices, ADAS systems rely on many of the vehicle’s other sensors to understand what the driver’s intent is. Sensors such as accelerator pedal position sensors and brake pedal position sensors tell the vehicle if the driver is intending to accelerate or slow down. Steering angle sensors and yaw rate sensors report the driver’s intended direction.

Tech Tip: ADAS Calibration

While many ADAS parts are plug and play, others need to be calibrated to operate properly. For instance, steering angle sensors need to be recalibrated or “zeroed” after every alignment. These often-overlooked sensors are crucial to proper operation of the vehicle’s ADAS system.

Some vehicle manufacturers will require a static calibration on a component, others will require a dynamic calibration, and some will require no calibration at all. When recommending and selling ADAS parts, always remind your customers that a calibration may be required after installation. Some ADAS parts like park assist cameras and sensors may not require any type of calibration, while others like cruise control distance sensors will almost always require calibration. It is also important to remember that it is the vehicle that determines if a part needs to be calibrated or not, not the part.

Returns are costly, especially on ADAS parts. If a customer tries to return an ADAS-related part, ask about the steps they took to calibrate the part after installation. The new part may not be defective. It is possible the correct calibration procedures were not followed.

ADAS Opportunities

Many times, when ADAS is mentioned, the collision industry comes to mind due to the number of ADAS components that are susceptible to being damaged in a collision. While this is true, as these systems age, there will be more and more repair and service opportunities.

Now that these systems are increasing in age and mileage, they are failing or coming out of calibration. For instance, the lenses of park assist cameras can become distorted over time. Cruise control distance sensors, lane departure cameras, and steering angle sensors are all critical safety features and can all be damaged by daily wear and tear.

In northern regions, these systems are prone to corrosion from the harsh winter driving and salt on the roads. In every region they are prone to water intrusion from rain, car washes, or flooding. While blind spot detection sensors are susceptible to accidents, they are also damaged by salt and road debris.

When these components fail, they will typically display a message on the dash and illuminate some sort of warning lamp. These are all indicators that typically steer the vehicle toward the general repair facility where the customer takes their vehicle for similar errors like a TPMS warning or Check Engine light. These shops will then diagnose, replace the part, and calibrate the system as required.

Keep in mind that with ADAS being a relatively new category, customers might not have complete understanding of the parts or may call them something different. It is wise to take an extra step to make sure your customer is getting the exact part they are looking for. For your professional customers, make sure they have looked at the part in the electronic catalog, and for DIY customers, open the box and review the part with them.

Helping You Help Them

The first step in selling more ADAS parts is letting your service provider customers know that you have them. Chances are they are still going to the dealer for these parts and may not think of you as a source.

The Standard® ADAS program includes over 550 part numbers, providing all of the aforementioned parts, from Blind Spot Detection Sensors to Cruise Control Distance Sensors, as well as Lane Departure System Cameras and Park Assist Sensors and Cameras. In total, the Standard® line of ADAS parts provides coverage for more than 280 million vehicles on the road. Gas, diesel, hybrid, or electric, import or domestic, Standard® has you covered.

For more information on diagnosing and replacing these components, search “ADAS” on the Standard Brand YouTube channel.

Sponsored by Standard®.