Wheel bearings keep the world rolling. The bearings allow wheels to rotate with minimal friction, and also help keep the wheels and hubs centered and aligned on their respective axle shafts or spindles.

Like many other parts in late-model vehicles, wheel bearings are engineered to last the service life of a typical vehicle. Many cars go to the junkyard with their original wheel bearings still in place. Yet others don’t make it that far and may fail at any point beyond 100,000 miles. The more the miles add up, the greater the chance of a failure.

Like many other parts in late-model vehicles, wheel bearings are engineered to last the service life of a typical vehicle. Many cars go to the junkyard with their original wheel bearings still in place. Yet others don’t make it that far and may fail at any point beyond 100,000 miles. The more the miles add up, the greater the chance of a failure.

Hard driving, aggressive cornering and racking up a a lot of miles on rough roads can all accelerate wheel bearing wear. Water (especially salt water) can also ruin a set of wheel bearings if the water gets inside the hub. This can happen if a vehicle is driven through hub-deep flood waters. Water inside the hub will degrade the grease and precipitate the formation of rust that corrodes the bearing surfaces.

The classic symptom of a wheel bearing that is failing is cyclic noise. Most often a bad bearing will produce a chirping sound or a growl, hum or squeal that changes in frequency with vehicle speed. The sound may come and go, or only be noticed when driving at a certain speed. In any case, noise from the vicinity of a wheel should always be investigated to find out what’s causing it. The noise or vibration could also be coming from a dragging brake pad or due to uneven tread wear on a tire.

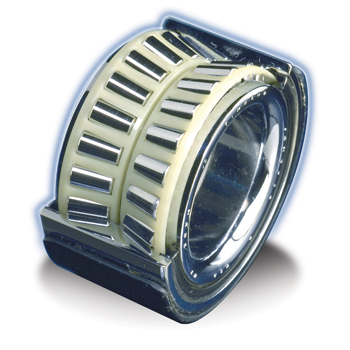

The wheel bearings on most late-model front-wheel drive (FWD) and rear-wheel drive (RWD) cars and trucks are part of a sealed hub assembly or are inside a sealed cartridge mounted in the steering knuckle. Unlike the serviceable wheel bearings in older vehicles that could be removed, cleaned and inspected, most wheel bearings today are sealed for life — which makes them difficult to inspect directly.

The best way to check a wheel bearing is to rotate the wheel by hand while feeling for looseness or roughness, and to rock the tire to check for play. Most sealed wheel bearings should have almost no play (less than .004 inches at most). If the bearings are loose or rough, they need to be replaced.

If one wheel bearing on a high-mileage vehicle has failed, chances are the other wheel bearings are probably reaching the same point and will have to be replaced soon. Recommend replacing both front wheel bearings, or all four wheel bearings at the same time to reduce the risk of a dangerous wheel bearing failure down the road.

Another reason why a wheel bearing may have to be replaced is if the wheel speed sensor inside is corroded or damaged, or has failed electrically. The wheel speed sensors in some hub assemblies can be replaced separately if there is a problem with the sensor, but on others the entire hub assembly has to be replaced if the sensor calls it quits (even if the bearings are still in good condition). It’s an expensive fix for an illuminated ABS light, but without the new hub and sensor the ABS light won’t go out and the ABS system won’t operate.

Replacing a bad wheel bearing often requires special tools: some type of hub puller for the front wheel bearings on many FWD cars and 4WD trucks, or a hydraulic press to replace the rear axle bearings on a RWD car or truck. It takes a certain amount of skill to do this job correctly, and if done wrong the new bearings may be damaged or fail prematurely.

A new hub or axle nut (and cotter pins) should always be recommended to customers who are replacing wheel bearings.

If a customer is repacking or replacing serviceable wheel bearings on an older car or truck, new grease seals are a must as is the proper wheel bearing grease. Ordinary chassis grease should never be used to lubricate wheel bearings. Always use a high-temperature wheel bearing grease that meets or exceeds the requirements for a moly-fortified NLGI No. 2 Grade LB Lithium 12-Hydroxysterate extreme pressure grease, or NLGI No. 2 Grade GC-LB Lithium Complex extreme pressure grease.

As a rule, conventional greases and synthetic greases are NOT compatible and should NOT be intermixed. If non-compatible greases are intermixed, the combination may break down and separate at high temperatures leaving wheel bearings high and dry without adequate lubrication.

On older vehicles without sealed wheel bearings, cleaning, inspecting and repacking the wheel bearings every 30,000 miles is usually recommended (more often if the vehicle is driven off-road or through hub-deep mud or water). On boat trailers, the wheel bearings should be repacked every season due to the fact that the wheels are often submerged in water.

Your customer may need a seal driver to install new grease seals on an older vehicle. Using a driver is important to make sure the seal is driven in straight, and is not bent or damaged during installation (which could cause it to leak).

When replacing wheel bearings on older vehicles that do not have sealed bearings or hubs, the bearings must be adjusted to allow the amount of play specified by the vehicle manufacturer. In most cases, tapered wheel bearings should NOT be preloaded.