This holiday season, many of us are concerned about the size of our belts – but that’s an entirely different topic for another type of magazine! Belt sizing is a year-round issue for parts specialists. Translating a belt’s length or markings into a usable part number can be challenging, especially given all the different ways customers present their requests.

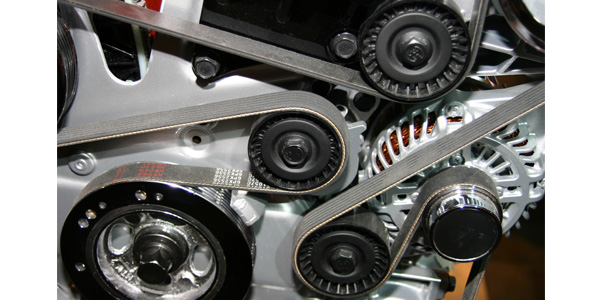

Serpentine belts are a common request, and many of these are simple cataloging exercises. Year, make, model, engine and maybe an option or two are easy enough to sort out. When these bits of information aren’t available, however, we must rely on the markings and measurements of the belt itself.

Each belt manufacturer has its own unique part-numbering system. An exhaustive explanation of each individual system is impractical here, but the part number generally will call out the number of ribs, as well as the length of the belt, and any special features. Special features might include double-sided belts like those used on some VW models, or improved construction and materials for heavy-duty applications.

Most U.S. aftermarket manufacturers use an English measurement system, where the length is expressed in tenths of an inch, but the worldwide industry standard is based on a metric measurement. This metric numbering is sometimes referred to as a “PK” number, and is found on most belts along with the manufacturer’s traditional part number. PK numbers contain three important pieces of identifying information.

As an example, “8PK2515” is the PK number found on an OEM serpentine belt. The first digit indicates an eight-rib belt, followed by “P” to identify metric belt sizing, and a “K” showing that this belt conforms to the SAE standard for rib sizing (3.56 millimeters wide for automotive-type serpentine belts). The final series of numbers is the effective length of the belt, given in millimeters.

The PK number can be used as an interchange if the manufacturer-specific part number is worn away, a section of the belt is missing or the manufacturer’s number is not interchangeable in your catalog.

We measure most belts around their outside circumference (A-, B- and C-series V-belts are numbered according to their INSIDE circumference, and are the most common exception to this rule), and on average, the outside circumference of a serpentine belt is about 14 millimeters larger than the effective length coded into the PK number. Our 8PK2515 belt would have eight ribs and an approximate outside circumference of 2,529 millimeters, or 99.57 inches. A quick check of the belt catalog’s progressive size listing would give the parts specialist the closest part-number matches in their product offering. Be careful not to deviate too far from the recommended size, as an over-length belt could slip or even jump its pulleys, and undersized belts can cause premature bearing wear on belt-driven components.

Considering that serpentine belts can ride on both grooved and smooth pulleys, the numbers may wear off the belt completely over time, and direct measurement is the only option for an otherwise unidentifiable belt. A cloth measuring tape (like those found in a sewing kit) can be helpful in getting an accurate measurement. Metal tape measures and rulers are too stiff for taking accurate measurements, and measuring a belt or belt drive with a piece of string can result in inaccurate measurements due to stretching of the string’s fibers.

By the way: Get your very own cloth tape. My wife was NOT impressed when I returned her sewing tape covered in greasy fingerprints. Sorry, Jessica!