Live axles, also known as solid axles, are still alive and well in light truck and some SUV applications, but even modern muscle cars like the Mustang, Camaro and Challenger now feature Independent Rear Suspension (IRS). The live rear axle still presents parts specialists with a number of unique bearing and seal designs that make each style of axle challenging to catalog, even if most of the solid-axle options we see today are for older vehicles.

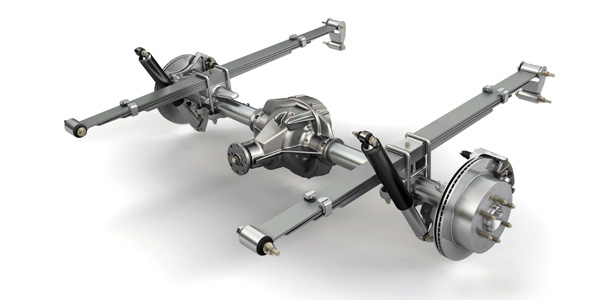

Axles are divided into two types: semi-floating and full-floating. In the full-floating axle, the shaft strictly transmits torque to the wheels, “floating” inside the axle tube, which supports the weight of the vehicle itself. The axle shaft is supported at the differential and by an outer wheel hub. The wheel hub contains two sets of tapered bearings and an inner seal, similar to the hub and rotor found on the front of many older rear-wheel-drive vehicles. Servicing the bearings and seals in these hubs often requires a few additional items. The axle shaft’s outer flange is bolted directly to the hub, with a thin metal gasket sandwiched between the two components. It is also common to see this joint sealed with RTV sealant, or with an O-ring seal. The flange gasket or seal is required, as gear lube from the differential flows through the axle tubes into the hubs. When servicing or replacing full-floater hub bearings, most manufacturers also recommend packing the bearings with an appropriate wheel bearing grease. Specialized sockets are required to remove and install the hub-to-spindle retaining nuts on many of these trucks.

Axle bearings and seals on the semi-floating axle are a little more straightforward, but also can be a source of add-on sales and service items. The semi-floating axle shaft actually carries its share of the vehicle’s weight, so damaged bearings also can affect the axle shaft itself. The outer axle bearing (also cataloged as the rear wheel bearing) may either be pressed into the axle tube, or pressed on to the axle shaft. Generally, axles that use a C-clip type retainer (most GM and Chrysler corporate axles, the Ford 8.8-inch and others) have a cylindrical roller bearing pressed into the axle tube. These bearings are easier to remove and install, but the differential cover must be removed to access the C-clips, so a replacement diff gasket (or RTV sealer) and gear lube are essential when replacing bearings and/or seals on these axle types. A bearing puller and slide hammer are necessary to do this job correctly. (And a magnet is pretty helpful too, for when you drop that C-clip into the drain pan full of used gear lube!)

The other type of semi-floater features bearings pressed on to the axle shaft, as well as a retainer flange and seal. The Ford 9-inch is the most common vintage example of this axle type, and a variation of the Dana 44, found on many later-model Jeeps, also features a maddening locking collar that causes headaches, even for dealership technicians. The old bearings (and locking collars, if equipped) can be carefully removed with a torch, cutoff wheel or cold chisel, but the new components must be pressed back onto the axle. This is a job best left to a professional, and your DIY customers should be referred to someone qualified to do this work, unless your store is already equipped with a press and provides this service in-house.