Because valve train timing repairs are becoming a primary part of your professional technician’s engine service market, it’s important to understand the basics of valve train timing. To illustrate, the camshaft controls the opening and closing events of the intake and exhaust valves in most four-cycle gasoline engines. The camshaft drive sprocket contains twice as many teeth as the crankshaft sprocket, which allows the camshaft to rotate at one-half crankshaft speed.

This gearing ratio allows the intake and compression strokes to occur on the first crankshaft rotation and the power and exhaust strokes to occur on the second rotation. A balance shaft might also be included in the valve train timing assembly to dampen engine vibration or an auxiliary shaft to drive the oil pump and distributor. Since the intake or exhaust valves can collide with the pistons when a timing belt or chain fails, it’s important to ensure a professional repair by selling timing gears, chains, or belts as complete replacement sets.

This gearing ratio allows the intake and compression strokes to occur on the first crankshaft rotation and the power and exhaust strokes to occur on the second rotation. A balance shaft might also be included in the valve train timing assembly to dampen engine vibration or an auxiliary shaft to drive the oil pump and distributor. Since the intake or exhaust valves can collide with the pistons when a timing belt or chain fails, it’s important to ensure a professional repair by selling timing gears, chains, or belts as complete replacement sets.

Push-rod engines

Because of their extreme reliability, meshed timing gears are generally used on push rod-type industrial and truck engine applications. Matching timing marks indicate when the crankshaft and camshaft gears are timed correctly. Some camshaft gears are made of a fibrous composite material designed to reduce gear noise. Many replacement gears are made of aluminum alloy, which normally produces a mild gear whine at idle speeds.

Most domestic push-rod V8 engines manufactured through the 1980s use a short timing chain to couple the camshaft and crankshaft sprockets and the service life on most is approximately 100,000 miles. Timing marks drilled or embossed on the gears allow the camshaft and crankshaft sprockets to be aligned along a vertical line drawn through the camshaft and crankshaft centers. As an exception, some older engines are timed by counting the number of timing chain pins between the timing marks embossed on the two sprockets.

Overhead camshaft engines

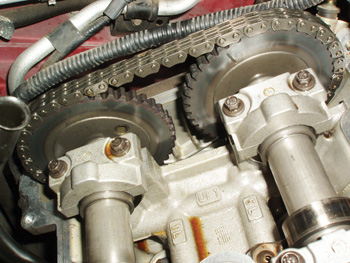

With advent of mass-produced overhead camshaft (OHC) engines during the 1970s, longer timing chains are now used to couple the camshafts with the crankshaft. Some engines use a primary timing chain to drive an intermediate shaft located just above the crankshaft. The intermediate shaft then drives a secondary timing chain attached to the driver’s side camshaft and a rear chain attached to the passenger side camshaft.

Many OHC engines use timing chain guides to align the timing chain (or chains) with the camshaft and crankshaft sprockets. A spring or hydraulically loaded tensioner compensates for normal wear in the timing chain links. A hydraulic tensioner uses engine oil pressure to tension the timing chain. In most OHC applications, the first components to fail are the timing chain guides. In any case, the chains, guides, tensioners and sprockets must be replaced as a complete set to ensure maximum reliability. Due to the reduced emissions-related maintenance that’s being mandated in some states, timing chains are once again becoming the preferred method of synchronizing the engine’s crankshaft with its camshafts and balance shafts.

Timing belts

Rubber timing belts have dominated the valve train timing market since they were popularly introduced on domestic vehicles in the 1980s. Due to the use of modern, crack-resistant EPDM rubber, visual inspections aren’t indicative of imminent failure. To ensure reliability, timing belts should be replaced according to the automaker’s recommended service intervals. While recommended replacement intervals on older applications often begin at 60,000 miles, that interval has generally been increased to 100,000 miles unless otherwise stated in the owner’s manual or professional service literature. To increase reliability, timing and balance shaft belts are generally sold as sets, complete with idler pulleys, and (if driven by the timing belt) a new water pump as well.