Replacement engine parts may be sold individually, in sets, or in complete overhaul kits. Or, the engine itself may be replaced with a factory “crate” engine or an aftermarket rebuilt engine.

To find the correct replacement parts, you must know the vehicle year, make and model, the engine displacement in cubic inches (CID) or liters (L), and often the engine code or vehicle identification number (VIN).

To find the correct replacement parts, you must know the vehicle year, make and model, the engine displacement in cubic inches (CID) or liters (L), and often the engine code or vehicle identification number (VIN).

The most common wear items in engines include the oil pump, valve guides, rod and main bearings, piston rings, timing chain and gears, camshaft and lifters and valve springs. The oil pump is often the highest wear component

because it runs on unfiltered oil. A worn oil pump will not produce normal oil pressure, which can cause accelerated wear and noise in the engine. If an oil pump is being replaced, a new pickup tube should also be installed. High-volume and high-pressure oil pumps are available for performance applications.

In Overhead Cam (OHC) engines that have a rubber timing belt rather than a chain to drive the cam(s), the belt usually has to be replaced at a specified mileage interval to reduce the risk of breakage. This can be serious in an “interference” engine that has tight clearances between the valves and pistons. If the timing belt fails, one or more valve may be hit by pistons, causing expensive damage.

In pushrod engines, the camshaft is mounted in the engine block rather than the cylinder head, and is driven by a set of gears or a timing chain. Timing chains can stretch at high mileage, but have no specified replacement interval. A worn timing chain can make noise from the front engine cover, and cause retarded valve and ignition timing (which hurts performance).

If a timing chain is worn or stretched, it should be replaced along with the camshaft and crankshaft drive sprockets (a complete timing set).

Most late model engines are factory equipped with aluminum crankshaft bearings, but older vehicles and performance engines are often fitted with tri-metal (lead-copper-babbit) bearings. Bearings can fail as a result of age fatigue, normal wear, oil starvation, severe overloading, dirt contamination or improper installation. Replacement bearings must be properly fitted to the size of the crankshaft journals, so bearings with undersized inside diameters are available to fit reground crankshafts. Installed bearing clearances should always be checked with Plastigage or a feeler gauge.

Most automotive pistons have three rings: a top compression ring, a second compression ring, and a one or three-piece oil ring in the bottom piston groove. Rings may be moly faced, chrome plated or nitrited for wear resistance. Rings can wear as the miles add up, and they can be damaged by detonation. Worn or broken rings cause a loss of compression, increased blowby into the crankcase, and increased oil consumption. Replacement rings must be the same size as the original, or oversized if the cylinders are worn and are bored to oversize to accept oversized pistons. A ring expander should always be used to fit new rings to the pistons as twisting can distort the rings.

Most cast iron cylinder heads (except big block Chevys) have integral valve guides, while aluminum heads have replaceable cast iron or bronze valve guides. The guide positions the valve stem, so clearances are very tight. Worn guides and valve guide seals are a common cause of high oil consumption and spark plug fouling because they allow oil to be sucked down the guide into the combustion chamber. Worn guides can be replaced, or the old guides can be reamed out to accept guide liners or new valves with oversized stems.

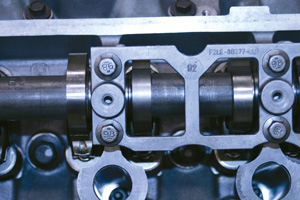

The valves in the cylinder head are opened and closed by the camshaft via lifters, pushrods and rocker arms in pushrod engines, or by followers or the cam lobes themselves in overhead cam engines. Late model pushrod engines use “roller” lifters that reduce friction. The lifters are also “hydraulic” and use oil pressure to maintain minimum valve lash for quiet operation. Hydraulic lifters also eliminate the need for valve lash adjustments (which were required in older engines with “solid” lifters).

The lobes on camshafts are hardened to resist wear, but wear may occur if the cam does not receive adequate lubrication or the oil does not contain adequate levels of high-pressure wear-resisting additive (such as ZDDP). Cam wear is rare on newer vehicles, but may occur on older vehicles with flat bottom (nonroller) lifters. Adding a ZDDP additive to the oil can prevent this type of wear.

If a camshaft is being replaced due to wear, or to upgrade performance, the lifters should also be replaced. Reusing old lifters on a new cam can damage the camshaft. The cam lobes must also be coated with assembly lube to protect them during break-in. A new timing chain is also recommended.

Valve springs can weaken with age, causing a loss in compression. Springs can also break. Weak or broken springs must be replaced. New springs are recommended for high-mileage engines and when installing a new camshaft.

Motor mounts hold the engine in place and dampen vibrations. Some mounts are solid rubber while others are fluid filled to add additional cushioning. Mounts should be replaced if collapsed, broken or leaking.