● SHOCK ABSORBERS — A component that dampens suspension motions to improve ride control and handling. The shock absorber is mounted near the wheel and connected to one of the control arms. Inside is an oil-filled cylinder with a piston and valves. Movement of the suspension forces the piston to push against the oil. This creates friction and resistance to dampen the suspension.

Two basic types: twin-tube and monotube. Twin-tube shocks have an oil reservoir around the outside of the piston chamber. Oil moves back and forth from the chamber through valves in the end of the shock. With monotube shocks, there is no outer chamber. One end of the shock is filled with pressurized gas and a floating piston seal separates the gas charge from the oil. Twin-tube shocks also may be pressurized with nitrogen gas (reduces cavitation, foaming and shock fade), but monotube shocks are usually charged at a much higher pressure (up to 360 psi).

Two basic types: twin-tube and monotube. Twin-tube shocks have an oil reservoir around the outside of the piston chamber. Oil moves back and forth from the chamber through valves in the end of the shock. With monotube shocks, there is no outer chamber. One end of the shock is filled with pressurized gas and a floating piston seal separates the gas charge from the oil. Twin-tube shocks also may be pressurized with nitrogen gas (reduces cavitation, foaming and shock fade), but monotube shocks are usually charged at a much higher pressure (up to 360 psi).

Shocks are a wear item and eventually lose their ability to dampen the suspension because of seal wear. A leaky shock must be replaced. Symptoms of worn shocks include a rough, bouncy ride, excessive body sway, bottoming or rocking after hitting bumps and poor handling stability. Worn shocks also can cause a cupped wear pattern on the tires, and may increase stopping distances on rough roads.

An easy way to check the shocks is to do a “bounce test.” Rock the suspension several times then release. If the vehicle continues to rock more than once, the shocks are weak and should be replaced.

Replacement shocks with larger piston bores, increased gas pressure, special valving, adjustable valving or other special features can be installed to upgrade ride control performance. Shocks are usually replaced in pairs.

Electronic shocks (and struts) have computer controlled valving that changes to suit driving conditions. These can be very expensive to replace, so conventional aftermarket shocks and struts are available as a repair alternative.

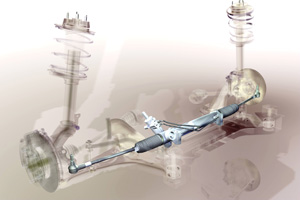

● STRUTS — Shock absorbers that are an integral part of the vehicle’s suspension. When used in the front suspension, the strut replaces the upper control arm and ball joint. MacPherson struts have coil springs around them while other struts do not. Like shocks, struts may be twin-tube or monotube and gas charged to improve fade resistance and handling.

At the top of front struts is a bearing plate that allows the strut housing to pivot when the wheels are steered. Looseness in the bearing plate can cause steering noise. Binding may increase steering effort and prevent the wheels from re-centering following a turn. The bearing plate can be replaced separately if necessary.

Struts should be replaced if the shock absorbing element is worn or leaking, or if the strut housing is bent or damaged. A bent strut will upset wheel alignment and may cause uneven tire wear or steering pull.

Replacing a strut that has a coil spring around it requires the use of a spring compressor. A better alternative is a complete strut assembly that comes preassembled with a new spring and is ready to install. It saves time and trouble. Wheel alignment should always be checked after a strut replacement.

● SPRINGS — Support the vehicle’s weight at each wheel. Various types include coil, leaf, torsion bar and air. Leaf springs are typically used on the rear axle only. Air springs (rubber bladders filled with air) are used on some vehicles with electronically controlled suspensions. Metal springs can sag with age, causing undesirable changes in wheel alignment. Springs should be replaced when ride height is less than specifications. Heavy-duty or “overload” springs are stiffer and may be recommended to increase a vehicle’s load carrying capacity. “Variable rate” coil springs combine different coil spacing to increase load capacity without sacrificing ride comfort. Springs are usually replaced in pairs. Aftermarket air springs or helper springs also can be installed to increase load carrying capacity. Conventional spring conversion kits are available for many vehicles that have factory-equipped air ride suspensions.

● BALL JOINTS — Connect the control arms to the steering knuckle. The joint has a ball-and-socket construction. The ball stud may ride against a metal gusher bearing, or a highly polished polymer bushing to reduce friction. Most low-friction ball joints are sealed and do not have a grease fitting for lubrication. Ball joints with a metal gusher bearing do have a grease fitting and must be lubricated periodically to flush out contaminants and keep the joint working smoothly. SLA (short-long arm) suspensions on rear-wheel drive vehicles have four ball joints: two upper and two lower on each side. Vehicles with front strut suspensions only have two lower ball joints. Some FWD cars also have ball joints in the rear suspension. Some ball joints are “load bearing” joints and carry most of the vehicles weight. Others are “non-load bearing” joints and support almost no weight. Because of the pounding they take, load bearing ball joints usually wear at a much faster rate than non-load bearing joints. Excessive joint play can cause suspension noise and undesirable changes in wheel alignment.

● STEERING RACK — Most vehicles today have rack and pinion steering that uses a pinion gear on the end of the steering input shaft to move a horizontal bar (rack) sideways. The rack is connected to the tie rods with sockets, which are enclosed in rubber bellows. The linkage has outer tie rod ends only. On some GM applications, a “center-mount” rack is used where the tie rods bolt to the center of the rack rather than the ends. Worn inner sockets can cause steering looseness and tire wear. Wear in a hydraulic power steering rack control valve housing can increase steering effort. Fluid inside the bellows indicates leaky seals and a need to replace the rack. Many newer cars are now equipped with electronic power steering that uses an electric motor on the rack or input shaft to provide steering assist.

● STEERING BOX — Older vehicles may have a recirculating ball steering gear in which ball bearings turn against the worn gear to move the steering linkage. The steering box is connected to the steering linkage with a pitman arm. An idler arm supports the other side of the linkage, which includes a center link, inner and outer tie rod ends and tie rods. Steering wander and looseness can result if the idler arm bushing is worn.

● POWER STEERING PUMP — Provides hydraulic pressure to assist power steering. May also provide hydraulic pressure for power brakes (Hydroboost applications). The pump is belt-driven by the engine. Noise and leaks are common problems that require replacing the pump. If the replacement pump does not come with a pulley, the pulley will have to be removed from the old pump and installed on the new one. The power steering fluid should also be changed when a new pump is installed.

● POWER STEERING HOSE — Carries high-pressure fluid from the steering pump to the rack or steering box, and low-pressure fluid back to the pump reservoir. Hose leaks allow fluid to leak out of the system. Replacement hoses may be pre-made or assembled using various end fittings crimped onto hose.

● POWER STEERING FLUID — A special type of fluid used in the power steering system. Some vehicles use automatic transmission fluid (ATF) in the power steering system, but most require a special fluid with additives for the seals. A low fluid level almost always means the system has a leak (check the hoses and steering rack or gear box). The fluid should always be changed when replacing a power steering rack or pump.

● TIE ROD ENDS — Flexible sockets that connect the steering linkage tie rods to arms on the steering knuckles. If worn, can cause steering looseness and tire wear. Left and right side tie rod ends are usually different and may have reversed threads.

● IDLER ARMS — Used in recirculating ball/parallelogram steering systems to maintain the proper alignment of the steering linkage. Mounted on the opposite side from the steering box and pitman arm, the idler arm pivots when the wheels are steered. Wear or looseness in the idler arm can cause steering play and wander.

● CONTROL ARM BUSHINGS — Provide support and cushion the hinge points of the control arms. Usually synthetic rubber (though some are plastic or metal), bushings can wear, crush or crack with age causing undesirable changes in wheel alignment. Some aftermarket replacement bushings are hard urethane plastic to firm up the suspension for improved handling performance.

Ignition System

Manual Transmission/Transaxle Parts

Emission Controls

Driveline Components