If you are going to give a customer the shaft, do it the right way. Make sure they get a FWD halfshaft that is the correct replacement for their vehicle.

FWD halfshafts come in various lengths and styles, and with different types of CV joints on the ends, and different spline counts and diameters. On some applications, different shafts are used with different transmissions (automatic or manual), and on many FWD applications, the right and left shafts are a different length. Whether or not an older vehicle is equipped with antilock brakes (ABS) also can make a difference in correctly identifying the application and which replacement shaft will fit it.

One way to make sure you don’t sell your customer the wrong shaft is to visually compare the original shaft with the replacement (new or reman). The diameter and appearance of the shafts will sometimes vary depending on the supplier and how much consolidation they have done with their product line. The important things that MUST match are the overall length of the complete halfshaft assembly (end-to-end), the spline count on the inner and outer CV joints (MUST match), the diameter of the inner and outer CV joints that fit into the transaxle and steering knuckle/wheel bearing assembly (MUST match), and – if the vehicle has ABS – the location and number of teeth on the ABS wheel speed sensor tone ring (which will be located on the outer CV joint housing). A mismatch in any of these critical dimensions will mean a misfit and a return.

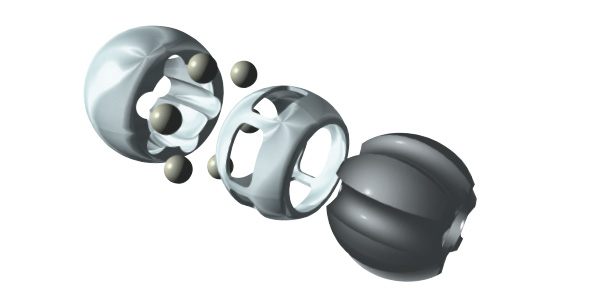

DIYers as well as professional technicians usually prefer a complete replacement halfshaft assembly because it is faster and easier to install. It saves time and trouble, because swapping CV joints on some applications can be tricky. Many applications also require special tools to crimp the protective bellow or boot clamps in place after replacing the CV joints. Replacing CV joints with CV joint grease also is a messy affair, something that’s not a concern with a complete halfshaft assembly.

Shafts may come with all new joints and boots, or remanufactured CV joints and new boots, or any combination thereof. Old boots should never be reused to save money, because a good boot is the only thing that stands between a CV joint and self-destruction. A tear or crack in a boot will spit out the grease inside the joint and allow dirt and water to enter the joint. If either of those things happen, rapid joint wear and failure usually follow within a few thousand miles.

The outer CV joints on FWD cars and minivans are usually the first ones to wear out and fail. A classic symptom of a bad outer CV joint is a clicking or popping sound that’s only heard when turning. A clunk or vibration that is heard or felt when accelerating or changing speed, on the other hand, usually indicates a bad inner CV joint. In either situation, the vehicle needs a replacement halfshaft.

Replacing a FWD halfshaft usually requires some disassembly of the front suspension. The knuckle usually has to be separated from the lower control arm by disconnecting the lower ball joint. A special tool may be needed to push the outer end of the shaft back through the wheel bearings, and a slide hammer or pry bar may be needed to separate a tripod or double-offset inner joint from the transaxle. On some older import applications, the knuckle may have to be removed so the outer CV joint and/or wheel bearing assembly can be disassembled using a hydraulic press.

Other items that should be inspected and replaced when a FWD halfshaft is changed are the grease seals on the transaxle. Close attention also should be paid to the condition of the control arm bushings, ball joints, shocks and struts and steering linkage.