Incorrect emissions repairs can lead to multiple and expensive jobs. Knowing the following visual clues for common oxygen sensor issues will prevent reoccurring problems and reduce the chance of returned parts and unnecessary warranties.

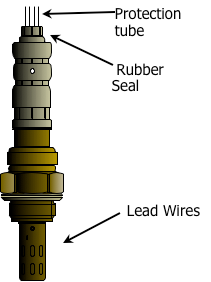

- Check for unusual colors on the protection tube (Figure 1). If there is a green, yellow or orange tint on the oxygen sensor protection tube (Example 1), the vehicle may have an internal coolant consumption problem and it is likely that all the oxygen sensors have been damaged. Finding and repairing the cause of the contamination will avoid damage to the replacement sensor.

Figure 1 – Oxygen Sensor

Example 1 – Anti-Freeze Contamination - Silicone poisoning is very common. Poisoning happens when incorrect or excessive sealant is used. Silicone poisoning creates a white powdery substance on the protection tube (Example 2), altering and even preventing reference air from entering the oxygen sensor. Advise the customer to look into components that may have excessive sealant (e.g. on the oil pan, gaskets, valve covers, etc.). When selling sealant to customers only recommend sealants labeled “sensor safe.”

Example 2 – Silicone Poisoning - Oil leaks are an often-overlooked cause for sensor failure. A vehicle with external oil leaks can result in multiple oxygen sensor replacements. For example, if a vehicle has a leaky valve cover gasket, oil may be leaking down the outside exhaust and into the oxygen sensor’s air ports. Internal oil consumption issues can also be observed by a sooty, gray ash color on the sensor’s protection tube (Example 3).

Example 3 – Oil Contamination - Check to see if anti-seize has accidentally been applied to the sensor’s protection tube. Anti-seize should only be applied to the sensor’s threads, in the smallest (pea-size) amount possible, to prevent contamination. Most sensors now come with anti-seize pre-applied to the threads.

- Make sure to look for more noticeable signs of damage to the sensor’s wire harness. Melted or frayed wires could indicate contact with the exhaust or incorrect routing of the sensor’s wires during installation. If the connector is installed before the sensor, twisting of the wire during installation could damage the sensor’s wire seal. Suggest that the replacement sensor be installed away from the exhaust and with some slack in the wire to prevent fraying.

Lastly, handle replacement sensors like you would a PCM: discard if dropped. Ceramic encases the sensing element inside of the oxygen sensor’s metal body. Cracked ceramic will allow exhaust gas into the reference air chamber. This will contaminate the reference air being read against the exhaust, ultimately skewing the PCM reading. This not easy to see without cracking a sensor open. When selling a replacement part, recommend handling with care.

This article was sponsored by NTK Oxygen Sensors. If you have questions related to emissions repairs or replacement sensors, contact NGK Technical Support at (877) 473-6767 option #2 or visit ngksparkplugs.com/products/ntk-oxygen-sensors for more information.