In today’s market, selling fuel delivery system parts often requires a high degree of product familiarity. Understanding the basics of how a modern fuel delivery system works not only makes your star shine a little brighter in your customer’s eyes, it also produces tangible results in your daily receipts. With that said, let’s look at the basics of how modern fuel

delivery systems work.

FUEL PUMP RELAYS

The fuel pump relay is an electric switch that’s commanded on or off by the Powertrain Control Module or PCM. When the ignition key is initially turned on, the PCM commands the relay to activate the fuel pump for approximately three seconds to pressurize the fuel system. When the ignition switch is turned to the “start” position and the engine begins cranking, the PCM again commands the relay to activate the fuel pump.

The fuel pump relay is an electric switch that’s commanded on or off by the Powertrain Control Module or PCM. When the ignition key is initially turned on, the PCM commands the relay to activate the fuel pump for approximately three seconds to pressurize the fuel system. When the ignition switch is turned to the “start” position and the engine begins cranking, the PCM again commands the relay to activate the fuel pump.

Once the engine starts, an engine speed signal from the crankshaft position sensor (CKP) indicates to the PCM that the engine is now running. If the PCM fails to receive a signal from the crankshaft position sensor, it will turn the fuel pump relay off.

To prevent discharging fuel from a ruptured fuel line, electric fuel pumps must be deactivated if the vehicle becomes involved in a collision. Many Ford vehicles, for example, use an inertia switch mounted under the dashboard to disconnect the fuel pump if the vehicle experiences a sharp impact. In other systems, the absence of a signal from a stalled engine will cause the PCM to turn off the fuel pump relay. A few systems will deactivate the fuel pump if the engine loses oil pressure or if the mass air flow (MAF) sensor fails to detect air flow into the engine.

Anti-theft devices may also be used to deactivate the fuel pump if the vehicle security or anti-theft system detects any type of tampering associated with vehicle theft. In the case of many General Motors vehicles, the engine will momentarily start and stall if the anti-theft system deactivates the fuel pump relay. Other anti-theft-related problems include defective ignition keys or key detection systems in the ignition switch.

MODERN FUEL PUMPS

MODERN FUEL PUMPS

The pressure required to vaporize the fuel in modern engines is generated by a high-pressure electric fuel pump

located inside the fuel tank. Depending upon the type of fuel injection system, most fuel pumps generate between 15 to 90 pounds per square inch of fuel pressure.

FUEL FILTERS

Many fuel pumps are protected from dirt by a fuel strainer attached to the fuel inlet. The fuel injectors are

protected by a fuel filter downstream of the fuel pump. It’s important to remember that in-line fuel filters are frequently neglected and should be changed at the first sign of fuel delivery system trouble. In contrast, many modern fuel filters are located inside the fuel tank on the inlet side of the fuel pump and are designed to last the life of the pump.

FUEL PRESSURE REGULATORS

The fuel pressure regulator ensures

accurate fuel delivery by precisely controlling fuel pump pressure. Fuel pressure regulators are configured into dual and single-line versions. Fuel pressure is controlled on dual-line fuel injection systems by an external fuel pressure regulator that returns excess fuel to the fuel tank through a smaller-diameter second fuel line.

Fuel pressure on dual-line regulators also is modulated by a vacuum hose attached to the engine’s intake manifold. When the throttle plate closes, high intake manifold vacuum causes the fuel pressure to decrease. As the throttle opens, low intake manifold vacuum causes the fuel pressure to increase. In some cases, the small rubber diaphragm inside the fuel pressure regulator diaphragm develops a small leak and allows fuel to leak into the intake manifold, causing the engine to run rich. This failure can be diagnosed by checking the vacuum line for the presence of liquid fuel.

Fuel pressure on dual-line regulators also is modulated by a vacuum hose attached to the engine’s intake manifold. When the throttle plate closes, high intake manifold vacuum causes the fuel pressure to decrease. As the throttle opens, low intake manifold vacuum causes the fuel pressure to increase. In some cases, the small rubber diaphragm inside the fuel pressure regulator diaphragm develops a small leak and allows fuel to leak into the intake manifold, causing the engine to run rich. This failure can be diagnosed by checking the vacuum line for the presence of liquid fuel.

Single-line fuel injection systems contain the fuel pressure regulator into the fuel pump assembly. These systems rely on the ability of the Powertrain Control Module (PCM) to maintain fuel control by changing the amount of time the fuel injector remains open. Dual and single-line fuel pumps and fuel pressure regulators can be diagnosed with conventional fuel pressure and volume testers.

PULSE-MODULATED FUEL PUMPS

Some modern fuel delivery systems eliminate the need for a fuel pressure regulator by controlling the fuel pump speed to change fuel pressure. These fuel systems are known as pulse-modulated systems because the fuel pump is powered by a series of electrical pulses that control the fuel pump’s speed.

In pulse-modulated systems, the PCM uses a fuel pressure sensor mounted on the fuel line to monitor fuel pressure. The powertrain control module (PCM) on pulse-modulated systems generally reduces fuel pressure at low-speed and increases fuel pressure at high-speed. Pulse-modulated systems also require a professional-grade scan tool to retrieve diagnostic trouble codes and to test the system by commanding the fuel pump to produce various pulse rates.

FUEL INJECTORS

Although chemistry and physics weren’t my favorite high school subjects, they do explain how fuel injection systems work. To illustrate the chemistry of combustion, 14.7 pounds of air are required to oxidize or burn one pound of pure gasoline. A chemically correct 14.7:1 ratio is called the “stoichiometric” air-fuel ratio, which means that only carbon dioxide and water remain after combustion takes place.

As for the physics of combustion, gasoline won’t burn until it’s vaporized into very small droplets. In modern engines, gasoline is vaporized by injecting it through a fuel injector nozzle under high pressure. Most fuel injectors are designed to produce a spray pattern very much like that of an aerosol spray can. If carbon deposits form around the fuel injector nozzle, the spray pattern becomes uneven. This causes some of the fuel to enter the cylinder in liquid form, which reduces fuel economy and performance.

As for the physics of combustion, gasoline won’t burn until it’s vaporized into very small droplets. In modern engines, gasoline is vaporized by injecting it through a fuel injector nozzle under high pressure. Most fuel injectors are designed to produce a spray pattern very much like that of an aerosol spray can. If carbon deposits form around the fuel injector nozzle, the spray pattern becomes uneven. This causes some of the fuel to enter the cylinder in liquid form, which reduces fuel economy and performance.

FUEL DELIVERY SENSORS

As mentioned above, optimum fuel control and emissions system performance occurs when the PCM establishes a 14.7:1 or stoichiometric air/fuel ratio. During a cold start, the coolant temperature sensor (CTS) and the manifold absolute pressure (MAP) sensor data allow the PCM to adjust the air/fuel ratio for quick starting and good cold engine performance.

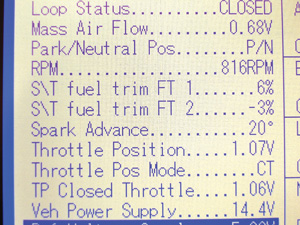

After the engine warms up, the throttle position (TPS), mass air flow (MAP), crankshaft position (CKP), coolant temperature (CTS), exhaust oxygen (O2), and other sensors provide electrical data inputs that allow the PCM to adjust the air/fuel ratio for optimum operating efficiency.

FUEL SYSTEM DIAGNOSTICS

To help mechanics quickly diagnose common fuel delivery system problems, auto manufacturers have built some very sophisticated on-board diagnostic systems into their powertrain control modules (PCMs). Because the PCM has the ability to detect a defective sensor by comparing its electrical output with that of at least two other sensors or by detecting open, shorted, and grounded sensor circuits, a scan tool is required to diagnose modern fuel delivery problems.

Last, the PCM constantly monitors fuel delivery system performance by monitoring oxygen sensor voltage. If fuel pump pressure is low or if a vacuum leak develops on the engine, the PCM begins holding the fuel injectors open longer to maintain correct oxygen sensor voltage. When this length of time exceeds 25 percent of normal, most PCMs are programmed to store a “lean” fuel trouble code in their diagnostic memories. Similarly, if the PCM reduces fuel injector on-time to compensate for a rich air/fuel mixture caused by a defective fuel pressure regulator, it will store a “rich” code in its diagnostic memory. With this information in mind, it’s important to remember that modern fuel delivery system performance is more about on-board electronics than it is about the mechanical aspects of the system.

Last, the PCM constantly monitors fuel delivery system performance by monitoring oxygen sensor voltage. If fuel pump pressure is low or if a vacuum leak develops on the engine, the PCM begins holding the fuel injectors open longer to maintain correct oxygen sensor voltage. When this length of time exceeds 25 percent of normal, most PCMs are programmed to store a “lean” fuel trouble code in their diagnostic memories. Similarly, if the PCM reduces fuel injector on-time to compensate for a rich air/fuel mixture caused by a defective fuel pressure regulator, it will store a “rich” code in its diagnostic memory. With this information in mind, it’s important to remember that modern fuel delivery system performance is more about on-board electronics than it is about the mechanical aspects of the system.

Gary Goms is a former educator and shop owner who remains active in the aftermarket service industry. Gary is an ASE-certified Master Automobile Technician (CMAT) and has earned the L1 advanced engine performance certification. He is also a graduate of Colorado State University and belongs to the Automotive Service Association (ASA) and the Society of Automotive Engineers (SAE).