It may be surprising to learn that leading causes of ignition coil damage have nothing to do with the coils themselves. Damaged or worn-out spark plugs, leaking valve covers and oil contamination are all culprits in ignition coil damage. Understanding ancillary ignition repairs and how they cause ignition coil damage will help advise customers and prevent unnecessary warranty returns.

A proper spark plug gap is crucial to an ignition system and the health of its ignition coils. As a spark plugs gap wears and becomes excessive it causes high secondary resistance. This resistance requires a higher voltage output from the ignition coil to bridge the gap of the spark plug. This increased voltage output can go beyond the limits of the ignition coil, resulting in premature wear, overheating or even melting of the coil.

Recommending the manufacturer’s gap specifications for replacement spark plugs will help ensure proper spark, proper ignition coil voltage output and prevent ignition coil damage.

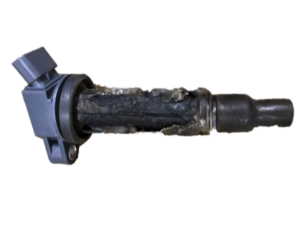

Oil damage is another cause of ignition coil repairs. If a customer comes in for parts relating to an oil leak, the spark plugs and ignition coils might also have been damaged and in need of replacement.

Many coil-on-plug ignition systems feature ignition coils mounted into a tube that is a part of the valve cover. Over time, the seal between the valve cover and the tube can fail, allowing oil to leak in and fill up around a spark plug and into an ignition coil. Advising that the root cause of the oil leak be repaired will prevent further damage to the ignition coils.

Spark plug flash-over leaves tracing or burn marks on the insulator of a spark plug and corresponding tracks inside of the ignition coil or coil-on-plug boot. These marks happen when the ignition coil voltage chooses the path of least resistance and grounds directly into the spark plug shell before reaching the spark plug ground electrode to complete combustion. When spark plugs are returned with signs of flash-over, advise replacement of spark plugs and ignition coils. The flash over creates a weak spot in the coil boot and needs to be replaced to stop flash-over from occurring on the new spark plug.

Dielectric grease is often overlooked during DIY installs. Recommending coils with pre-applied dielectric grease will help DIY-ers achieve proper connection to the spark plugs during install and protect the ignition circuit from moisture.

Understanding the visual cues of ignition coil damage will not only help a customer find the right replacement parts, but it will help prevent the same repairs from reoccurring.

This article was sponsored by NGK Spark Plugs. If you have questions about ignition coils or ignition related damage, reach out to NGK Technical Support by calling (877) 473-6767 prompt #2 or visit www.ngksparkplugs.com/ignitioncoils for more information.